SETHYEA

Production of innovative high energy efficiency pipes for underfloor heating-cooling systems

T1EDK-02611

with the co-funding of Greece and European Union

OBJECTIVE

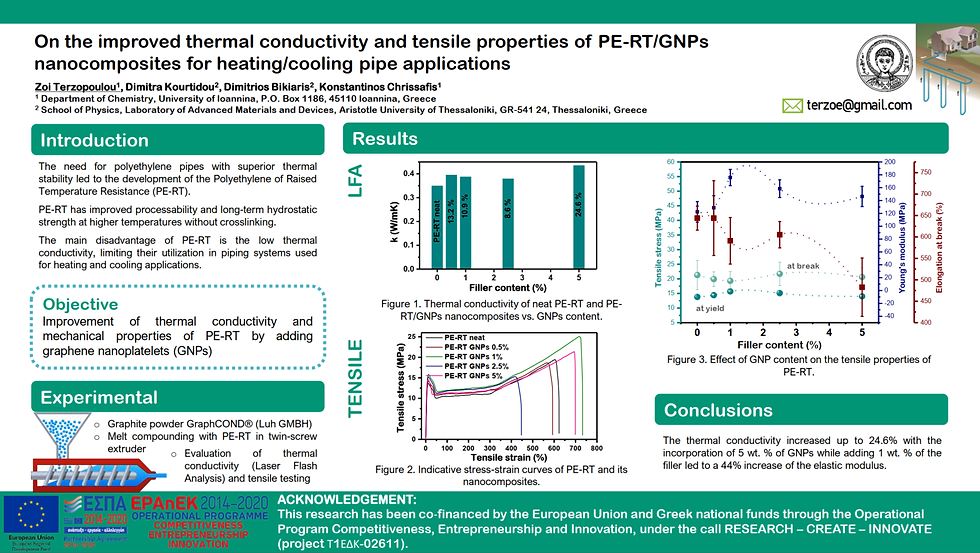

The production of low cost, energy-efficient cross-linked polyethylene pipes for geothermal applications.

Principal Investigator: Prof. Dimitrios Bikiaris

Coordination: Interplast SA Prof. Dimitrios Bikiaris

Geothermal energy is the energy stored in the form of heat below the Earth’s surface. Similarly to solar energy, it is a renewable and sustainable, infinite source of energy. Geothermal heat pumps take advantage of the almost constant temperature found at relatively shallow depths of the Earth’s crust (5-100 meters). Indeed, at these depths, a constant temperature is maintained throughout the year, around 15-18 °C for Greece. A geothermal heating (or cooling) system is composed of an underground external pipe network, a heat pump, an indoor set of pipes and a fluid, generally a mixture of water and propylene glycol, which circulates within this closed system. The operating principle is rather simple: during winter, heat is absorbed from the ground and is used to heat the fluid and thus the building. During summer the process is reversed.

The pipe network is very important for the performance of the heating system. Indeed, the pipe network must efficiently conduct heat from the ground to the internal fluid, or vice versa. Additionally, pipes should be able to withstand high temperatures and pressures. Plastic pipes, generally high-density polyethylene (HDPE), are preferred to steel pipes because of their higher resistance to corrosion. However, besides lower mechanical properties, plastic pipes have also low thermal conductivities, thus limiting the potential of geothermal pumps.

SETHYEA aims at improving the thermal conductivity of polyethylene by incorporating graphite additives, for the production of high-performance pipes. Two types of polyethylene were selected: crosslinked polyethylene (PEX) and low-density PE-RT polyethylene. PEX is a type of polyethylene which has improved mechanical properties while PE-RT has an important flexibility. Graphene, on the other hand, is a conductive material and its incorporation in polyethylene is expected to increase its thermal and electrical conductivity. Different types of graphene will be investigated, but all of them will be in the form of nanometric particles, in order not to alter the mechanical performances of PEX and PE-RT. Although the final pipes will be more expensive than regular HDPE, they are still expected to be reasonably priced, due to the low cost of graphene.

The consortium which has come together for the implementation of this project is composed of:

-

the Ceramics and Composites Laboratory of the University of Ioannina, which will prepare the graphite nanoadditives,

-

the group of Prof. Bikiaris, of the Laboratory of Chemistry and Technology of Polymers and Dyes, that will prepare the polyethylene-graphite materials and chemically characterize them,

-

the group of Prof. Chryssafis, of the AMDe Lab, which will carry out all the physical characterizations of the obtained materials, and

-

the company Interplast S.A. that specializes in the manufacture of plastic pipes and will produce pipes from selected PEX-graphene and PE-RT-graphene materials.

SETHYEA was succesfully completed in 25/06/2022.

Publications

Posters in scientific conferences